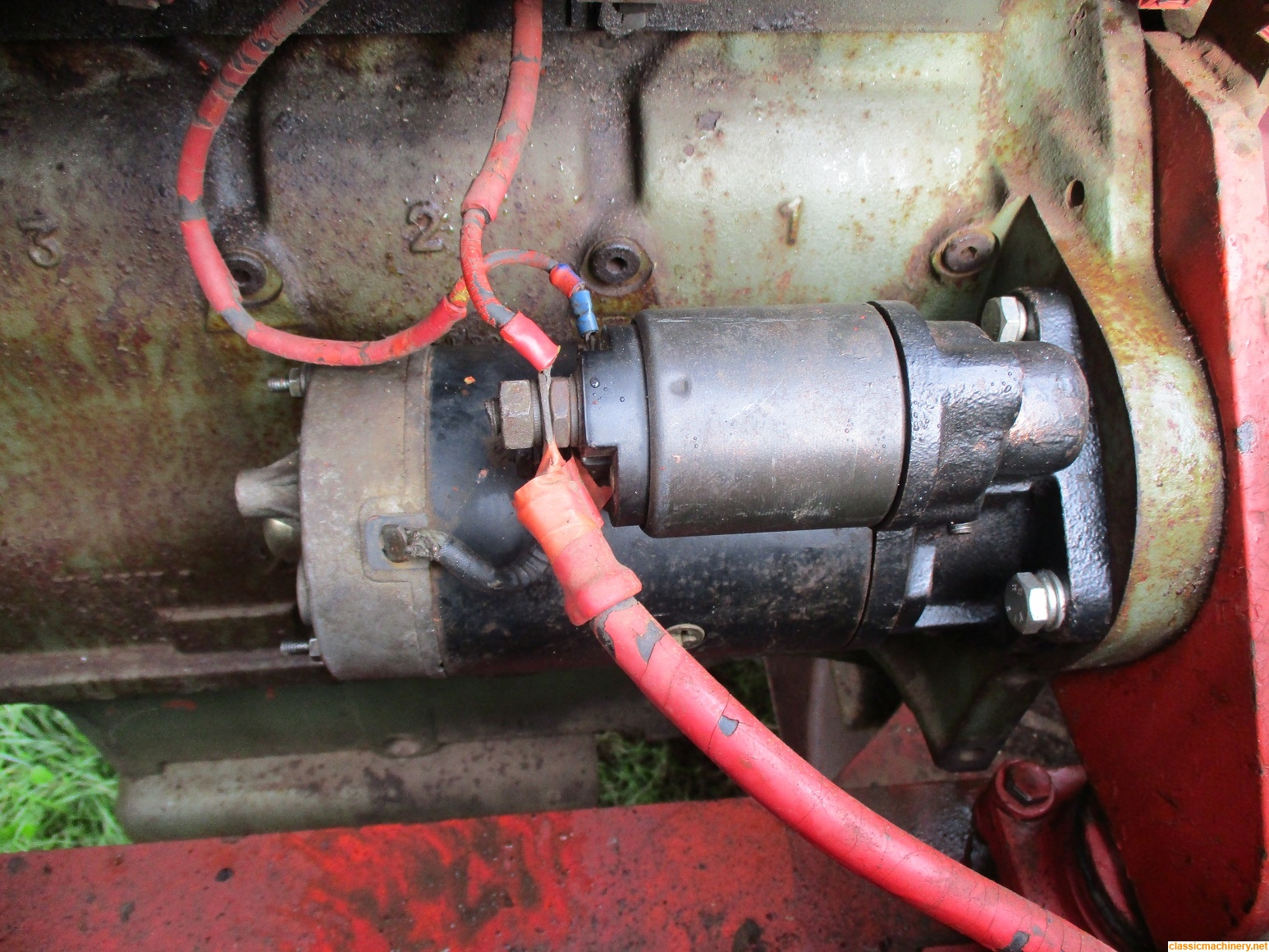

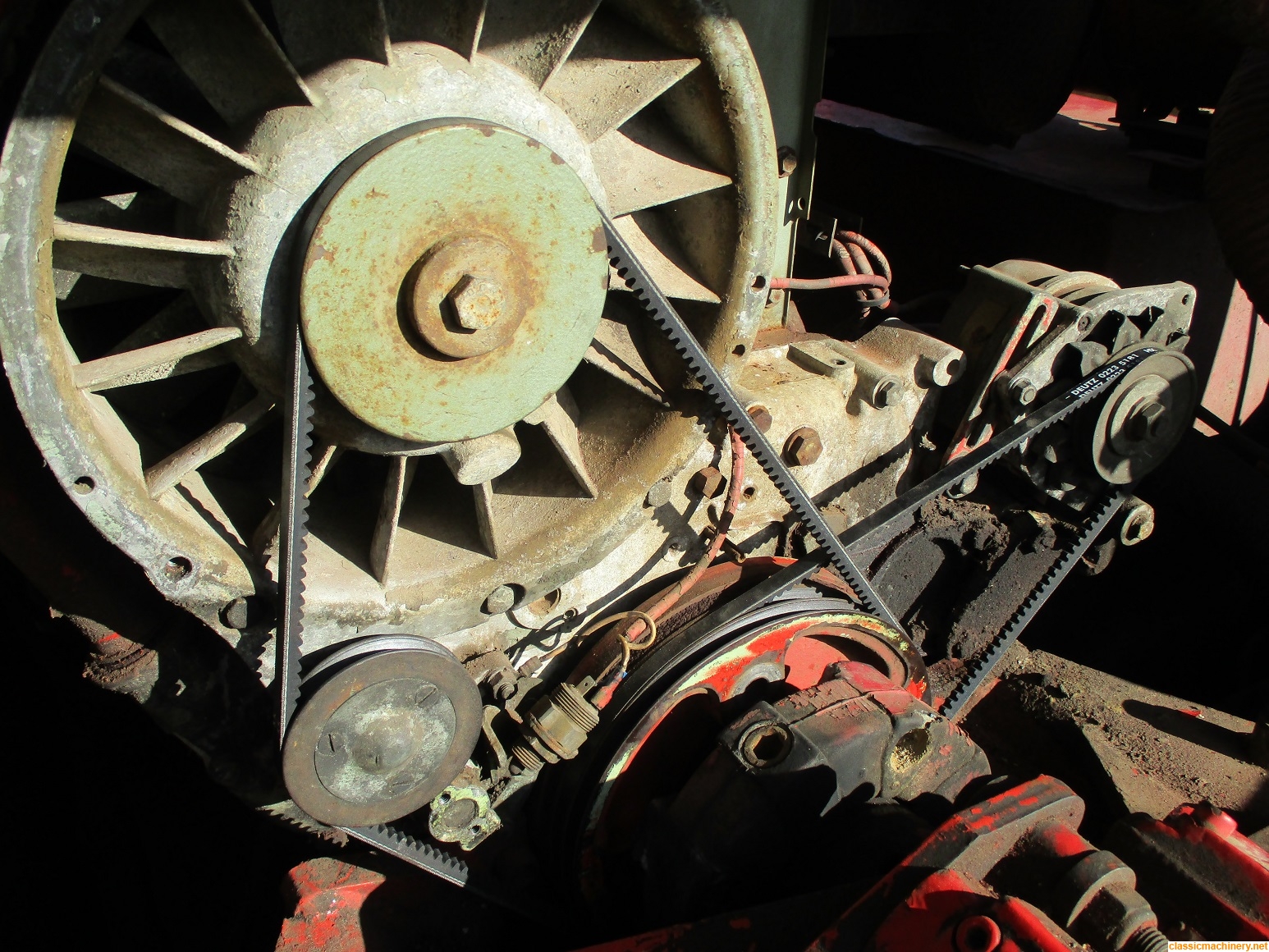

AJ. wrote:The starter not engaging is usually caused by the clutch in the Bendix drive slipping,very common fault with the Bosch starter,I used to carry a spare Bendix to save time taking the starter to the repair shop,the cooling belt coming off is a serious issue,the engine must not be run without the belt as the cooling fan will not be working and the engine will over heat and seize up fairly quick,check why that is happening see the jockey wheel is not slopping about and the fan bearings are good,the jockey wheel has a warning switch that should be working to alert the operator if the belt fails,on the engine side of the fan there is a cover held on with two over centre clips,that cover needs to be removed and the cylinder barrels and heads blown out to get rid of any debris/dust in there that could impede the cooling,one cannot put enough empathises on the cooling of those engines which its often overlooked it, you have smartened it up real nice well done .

AJ

AJ Thanks, I ran the engine and watched the jockey pulley it does move and slop about a bit specially when the engine is on tick over does this mean that the spring is weak? When I put the belt back on the spring felt like it had plenty of tension to me, what did you normally find was the cause? The engine does have a warning switch that is supposed to operate the horn if the belt fails or comes off but this does not work which for a machine of her age comes as no great surprise.

How difficult is the Bendix to change on the starter; I would assume that you remove the starter and strip it from the back?

Cheers

Jeremy