Page 1 of 2

Help Any JCB service engineers here

Posted: Sat Jun 04, 2016 10:05 am

by davidbrown80

hi

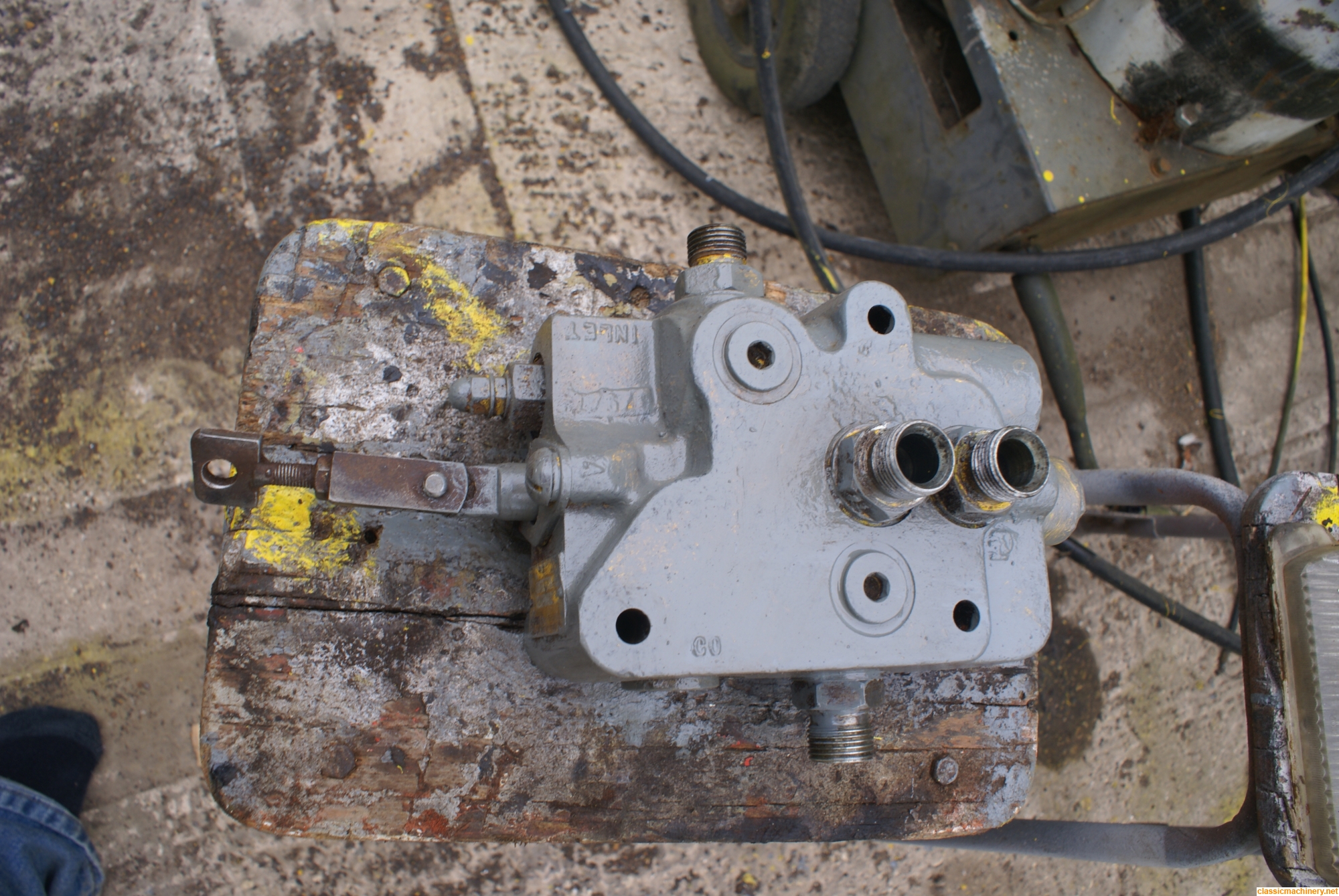

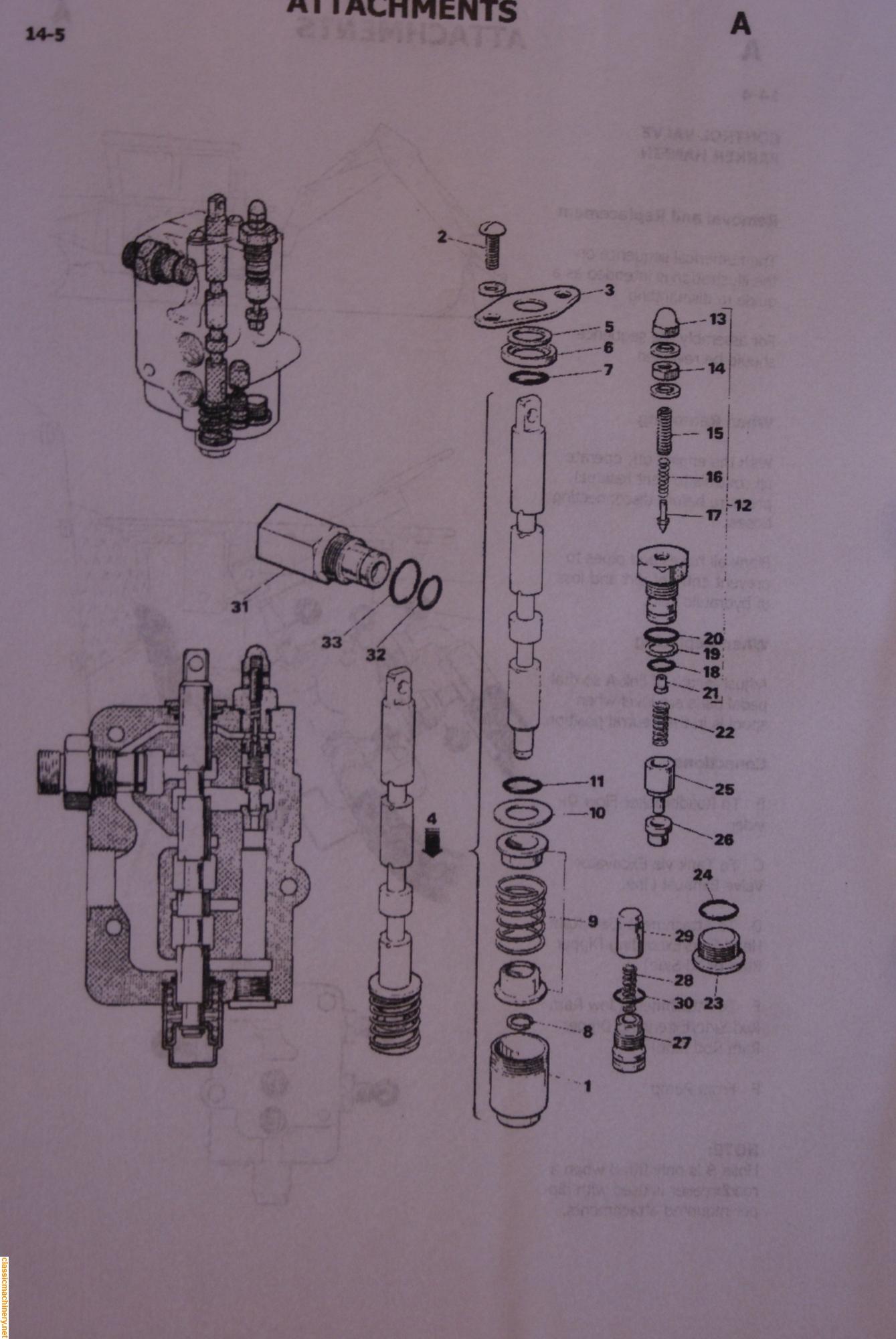

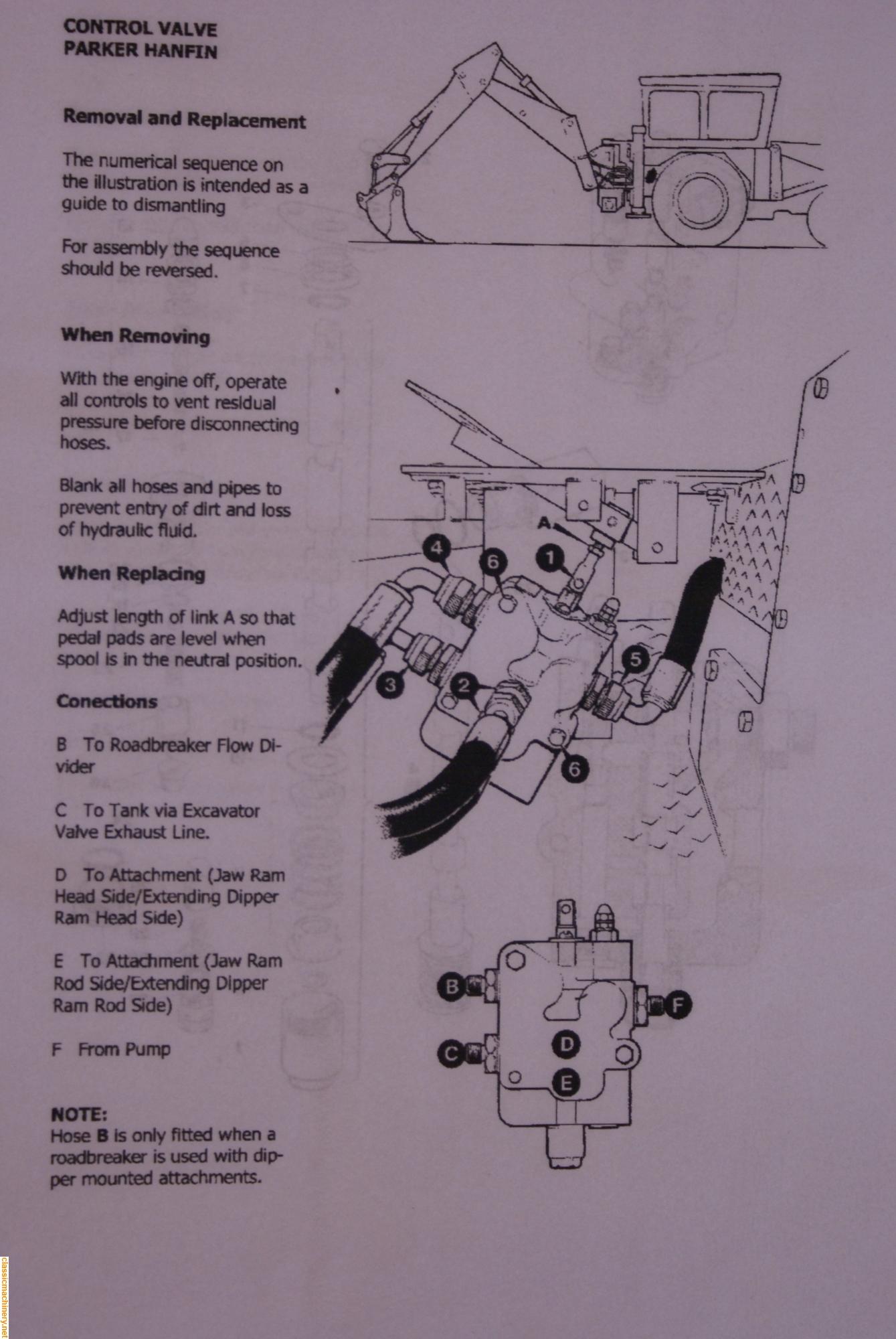

Im trying to rig up my JCB 3C MK3 with extender dig with a pecker roadbreaker , the controll for the extender is a parker hanfin block which according to the workshop manual as a blanking plug in one of the ports which it has and it says its for the road breaker diverter valve

so therefore can i just takeout the blanking plug and fit the supply pipe to the breaker/pecker from there and operate useing the extender pedal ? or do i have to forget that and use one of the extender ports through a new diveter valve and use that as the supply ?

im sure that one of you JCB gods outthere will know the answer.

Thanks in advance for any info.

Re: Help Any JCB service engineers here

Posted: Sat Jun 04, 2016 10:15 am

by Mrsmackpaul

do you know if it has closed center or open center hydraulics ???

And no I know absolutely stuff all about JCB hydraulics but oil is oil I guess and it all sort of flows under pressure if that makes any sense so we should be able to sort it

Paul

Re: Help Any JCB service engineers here

Posted: Sat Jun 04, 2016 11:05 am

by davidbrown80

Re: Help Any JCB service engineers here

Posted: Sat Jun 04, 2016 10:17 pm

by Mrsmackpaul

If Im looking at this right when you want to use the road breaker you push the foot on the pedal ???

And looks like you also push the pedal operate a lever to extend the dipper ??

that looks a power beyond fitting that screws into the valve block so the oil doesnt bypass straight to the tank again and flows thru the breaker instead

so you need to get what we call a power beyond fitting its like BSP coupling you have port C only longer to reach further down divert the flow back to the tank looks like it has a O ring on it as well

JCB.JPG

the red do hicky I would call a power beyond fitting

not sure if the blue one is what that is but I would expect it to be something like that with a couple of O rings on the bottom some thread and hex and some more to screw the hose to

hope this is of some help dunno whats happened to the rest of the brains trust on here come on fellas chime in and help if you can even if it is shut you fool Aussie you have it all wrong LOL

From what I can see thats all you need as shown in the drawings if you take the to your hydraulic shop and the spool valve they should be able to give you the right fitting off the shelf I would think

Paul

Re: Help Any JCB service engineers here

Posted: Sat Jun 04, 2016 11:56 pm

by FOWLER MAN

Hi,

I know this is not the info you are really looking for but in years gone by I fitted hammers to JCBs, Priestmans, Hymacs and others without the need of an operating valve at all.

If the job called for a hammer on a machine that wasn't piped all that was required was to cable tie a pair of flexy pipes along the boom and dipper.

The pressure pipe either 1/2" or 5/8" and the return 3/4" or 1" according to the size of the machine and hammer.

You then need a pair of "self seal" couplings to attach and remove the pipes from the hammer.

At the machine end simply "T" the smaller hammer feed into the pressure down pipe on the bottom of the back-actor hoist ram.

"T" the larger return pipe into the machines return line filter feed. "T" in so that the oil returning from the hammer goes through the filter before reaching the tank. This was only a mornings work if you knew what "T" fittings you needed.

The digger will then operate normally till the point engages the work. Continued downward pressure applied by the boom hoist lever will then operate the hammer.

The hammer does not have to be in a vertical position, it will operate at any required angle and you have as much control as with any other system.

As soon as the pipes are removed at the hammer the machine will return to normal operation.

Fred

Re: Help Any JCB service engineers here

Posted: Sun Jun 05, 2016 10:20 am

by davidbrown80

forgot to ask if i can get a power beyond fitting when would the hammer work ? by pressing which pedal extender in or extender out as theres only two pedals i assume one must play both roles?. if i cant rig it as is shoud be then perhaps fowler man could send me a sort of circuit diagram if poss please

Re: Help Any JCB service engineers here

Posted: Mon Jun 06, 2016 12:59 am

by FOWLER MAN

Hello again,

I think the "Road Breaker" circuit you have been looking at in the manual is intended to operate the hand held hammers in the illustration below.

To pipe up your hammer to operate from the hoist lever simply "T" the hammer feed into the connection at the bottom of the hoist ram.

That should be easy enough as it is the connection which you can see right in front of you as you look through the back window, the one which goes straight in, not the one that runs along the ram and in at the far end.

If I remember rightly, (again facing the back), you will find the return line connected to the left hand end of the valve block. It will be a large pipe running directly to the top of the filter where it dumps the return into the reservoir via the filter. You need to "T" your return into this line wherever you can. ( I think JCB called it the exhaust line, not return line).

That's all that's to it.

Some JCBs were fitted with dual pumps to work with larger hammers.

Fred

Re: Help Any JCB service engineers here

Posted: Mon Jun 06, 2016 8:58 am

by davidbrown80

hi

my machine as the dual pump fitted but i think your method sounds the way to go. thank you for your help

Re: Help Any JCB service engineers here

Posted: Wed Jun 08, 2016 1:29 pm

by davidbrown80

im now told i need a hammer controll valve that screws into the extender dig valve block and take the hammer feed direct from there ? does anyone here know of a hammer controll vale ? could it be that easy !!!!!!!

Re: Help Any JCB service engineers here

Posted: Wed Jun 08, 2016 9:52 pm

by Mrsmackpaul

I would think that would be correct as thats what the power beyond does is gives you availability to screw a extra spool valve on to the existing spool valve and then you can work the lot independently

Any spool valve of correct pipe fitting size and flow rate should be fine

Does your loader have a 4 in 1 bucket ????

The spool valve I would guess would need to fitted wit a indent so once the spool is operated it holds that position until you turn it of unlike your normal loader or back ho spool valve once you take your hand off them they return to off position

These things are common off the shelf type items so should be cheap as chips and easy to find

once you fit this spool and plumb it up to the end of the backhoe you will be able to run a whole host of stuff like a bobcat can but out on the end of the boom there will be some work in plumbing it all to the end of the backhoe but once I I think you will find it worth while

If you got a duel spool valve you may find a little quick hitch you might want to fit out to the backhoe as well one day just thinking a head and I think they call that future proofing it even if you never ran the pipes for the quick hitch the spool is there

If it was me I would take some time and run some neat pipes and hoses out to the end I dont think you would ever regret it

Paul

so therefore can i just takeout the blanking plug and fit the supply pipe to the breaker/pecker from there and operate useing the extender pedal ? or do i have to forget that and use one of the extender ports through a new diveter valve and use that as the supply ?

so therefore can i just takeout the blanking plug and fit the supply pipe to the breaker/pecker from there and operate useing the extender pedal ? or do i have to forget that and use one of the extender ports through a new diveter valve and use that as the supply ?