Did you use copper spray I seem to re call mentioning that in a previous thread ( sorry if I forgot to mention that ) I maybe wrong there, torque it down this time and leave the rocker cover off when running till its warm and keep on retorquing it around and around and around a whole heap of times till the motor is warm stick a sheet of card board in front of the radiator will warm up much quicker have plenty of rags at hand as some oil will no doubt spill with it running with out the rocker cover on

hope this helps all good advice

Paul

Also something to think about the head gasket doesnt seal on the block as such for the compression it seals on top of the sleeve so if its stick proud and all the sleeves are stick proud around about the the same like withing a few thou head gasket should seal up fine as stormin said a steel rule can help in checking this by using feelers gauges between the sleeves and measure the height but I doubt this is a problem but it should be checked just make sure

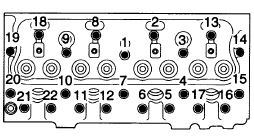

make sure you torque the head in the right sequence start from the middle and work out

If the torque is meant to be say 70 pounds always start off a lot lower say around 40 run around the head then 50 around the head again and 60 and so on slowly increasing till it torqued down properly and always in the same order start from the middle and work out

check your tension wrench is working right I cant stress this enough check it with someone elses once you start off low on the torquing grab a mates tension wrench and just go over the same studs again with a different tension and check its clicking at the same time

I never really do any of this to this extreme only when I have problems and twice I have found the tension wrench to be faulty as in once broke head studs the other time to loose then went and bought a real high quality tension and really look after it and have never had another problem