There is still the niggling issue of the two speed track problem with this digger; after much ado I have now got two contacts that can give me some help, one in the form of Generation Deux who are the French Poclain enthusiasts and a chap I got talking to at Andrew's event who used to work on Poclain machines. I was recommended by the chap I met at the working event to swap over the two track spools that are fitted to the outside of the track drive motors, and the gent from France advised me to strip the spool.

Now for me the big issue was that I really did not fancy draining off all the hydraulic oil again and as these components are at the very bottom of the machine, if I swapped them around then unless I had drained the oil there would have been a mess everywhere plus the added cost of new oil. I decided to strip down the suspect component in-situ now there would still be some oil loss. Part of the problem is that the piston/spool inside the unit has a couple of springs fitted behind it although the piston can be hard to remove because of oil suction.

The last thing I wanted was for all the bits to suddenly spring out and fly allover the place, so I made a tool to hold the cover in place while I removed the circlip holding the lot in.

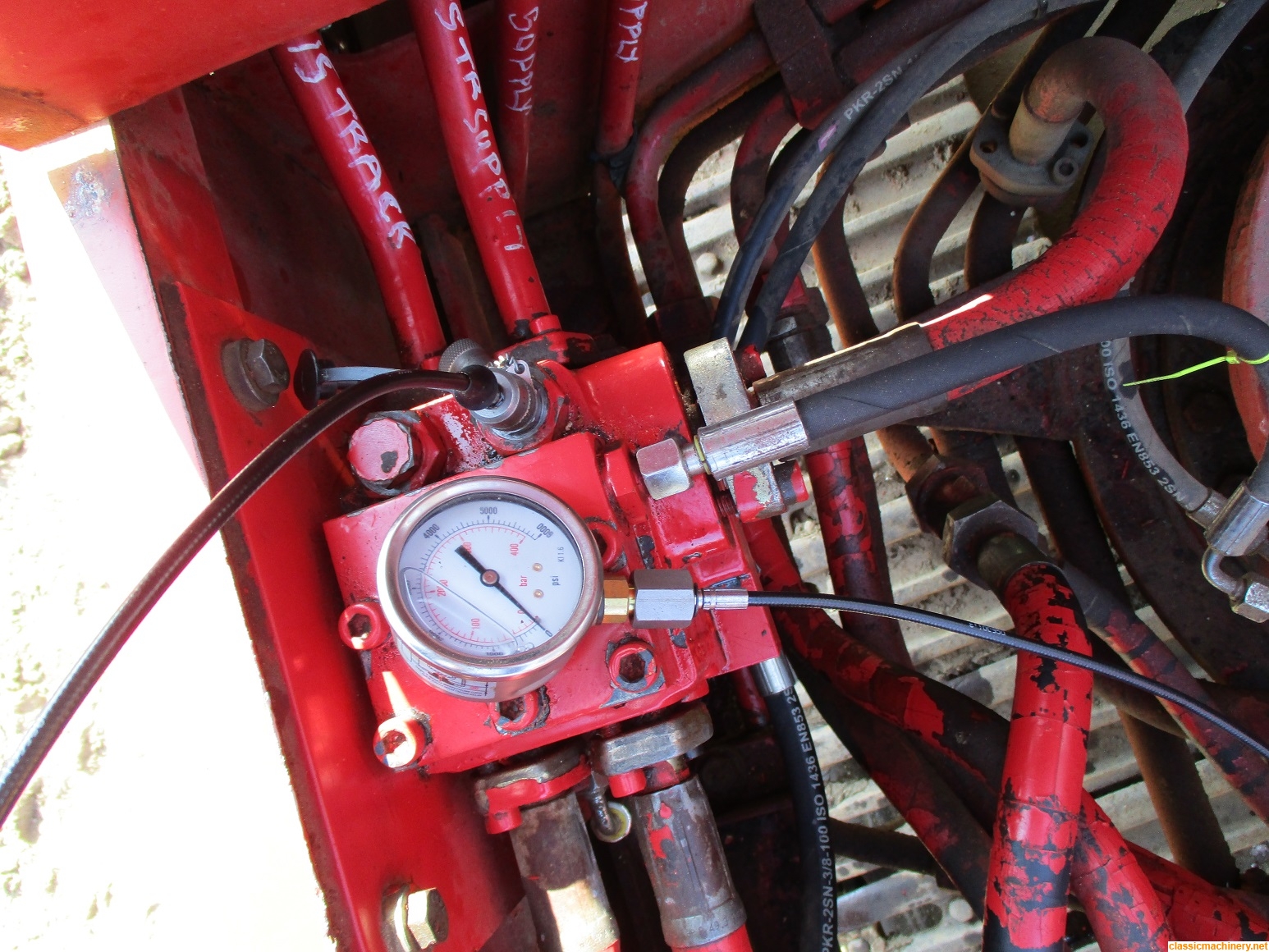

Naturally sods law applies as always and after much of a struggle I finally got the circlip out, it was only then that I could fit my homemade tool, the next issue was that the plug covering the bits was seized in and there is no way to lever it out. Finally I fitted the tool and left only a small gap between the bolt and plug then started the digger and carefully operated the track drive pedal letting the hydraulic pressure free the plug and blow it out, the tool stopped the plug from flying right out. I removed the piston, took the plug out of it and checked the spool inside it, no problem there, removed the springs they too were okay, so a pretty fruitless exercise, at least I can rule that issue out now, so I put the lot back together again.

Jeremy